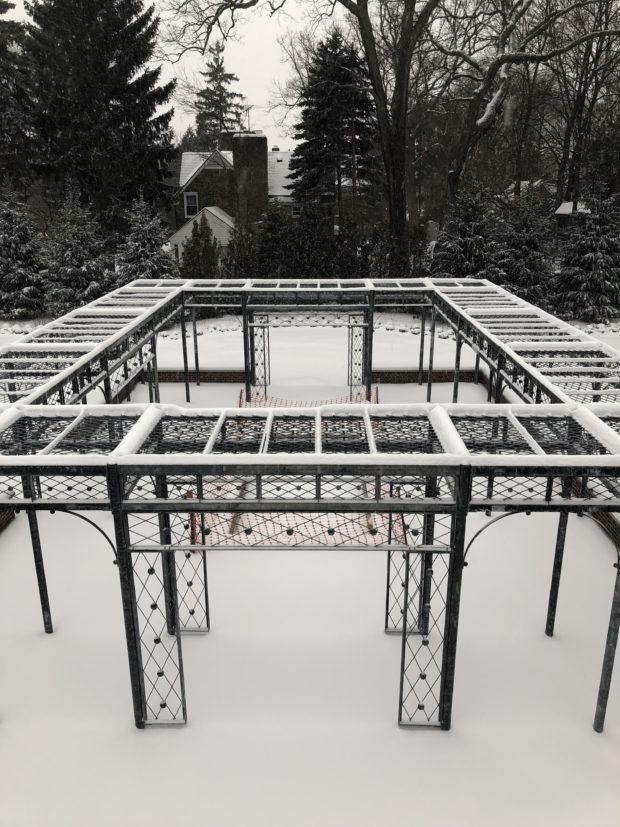

I am several years into a landscape project with great and ever so patient clients. In 2019 we removed their old dysfunctional driveway, regraded the entire front yard, and added back a new driveway and a landscape to go with. So far, so good. The back yard has been the subject of our efforts for better than a year. As the house is built on and into a steep hill, the rear yard had no flat usable space outdoors. Unless you count the 400 odd square feet pictured in the photo above. A large scale ipe deck with a swimming pool – part of which is cantilevered over an 11 foot drop in grade – has strongly addressed that problem. They like to entertain, and they are actively involved in supporting their greater community. They also like spending time out of doors. They were keen to create a place that would be beautiful and functional. The deck and pool were monumental undertakings, due to the sheer size, the difficulty accessing the site, and the extreme grade. We are very near the end of that part, but for the glass rails that will surround the deck. I am hoping the project will be entirely finished by the end of May, so they have the rest of this season ahead of them to enjoy it.

I am several years into a landscape project with great and ever so patient clients. In 2019 we removed their old dysfunctional driveway, regraded the entire front yard, and added back a new driveway and a landscape to go with. So far, so good. The back yard has been the subject of our efforts for better than a year. As the house is built on and into a steep hill, the rear yard had no flat usable space outdoors. Unless you count the 400 odd square feet pictured in the photo above. A large scale ipe deck with a swimming pool – part of which is cantilevered over an 11 foot drop in grade – has strongly addressed that problem. They like to entertain, and they are actively involved in supporting their greater community. They also like spending time out of doors. They were keen to create a place that would be beautiful and functional. The deck and pool were monumental undertakings, due to the sheer size, the difficulty accessing the site, and the extreme grade. We are very near the end of that part, but for the glass rails that will surround the deck. I am hoping the project will be entirely finished by the end of May, so they have the rest of this season ahead of them to enjoy it.

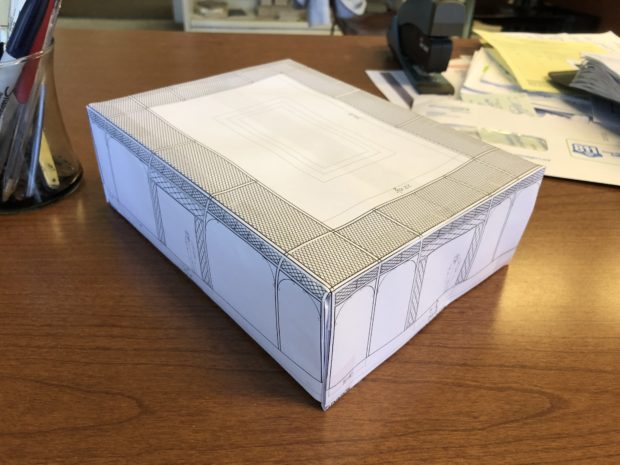

One component of that landscape was a pergola to be fabricated at Branch. Those of you who follow this blog know that I bought a 7 acre property with industrial buildings and large capacity bridge cranes in 2004, with the express idea of designing and fabricating heirloom quality objects for the garden in steel. We have been at exactly that over the ensuing years. The years have provided an opportunity to tune up fabrication protocols. And they have provided a framework for the evolution of design. Our original pergolas from years ago were designed primarily to provide large scale, organizing structure to a landscape. Seating areas under them naturally came to mind. They also could support large growing lax vines. Think climbing roses, climbing hydrangea, grapes and wisteria, or sweet autumn clematis. Both the strength of the steel and the permanent performance of the finish made them a great partner for vigorously growing vines that would put on weight, year after year. Those leafy plants that eventually grow over the roof would eventually provide shade.

One component of that landscape was a pergola to be fabricated at Branch. Those of you who follow this blog know that I bought a 7 acre property with industrial buildings and large capacity bridge cranes in 2004, with the express idea of designing and fabricating heirloom quality objects for the garden in steel. We have been at exactly that over the ensuing years. The years have provided an opportunity to tune up fabrication protocols. And they have provided a framework for the evolution of design. Our original pergolas from years ago were designed primarily to provide large scale, organizing structure to a landscape. Seating areas under them naturally came to mind. They also could support large growing lax vines. Think climbing roses, climbing hydrangea, grapes and wisteria, or sweet autumn clematis. Both the strength of the steel and the permanent performance of the finish made them a great partner for vigorously growing vines that would put on weight, year after year. Those leafy plants that eventually grow over the roof would eventually provide shade.

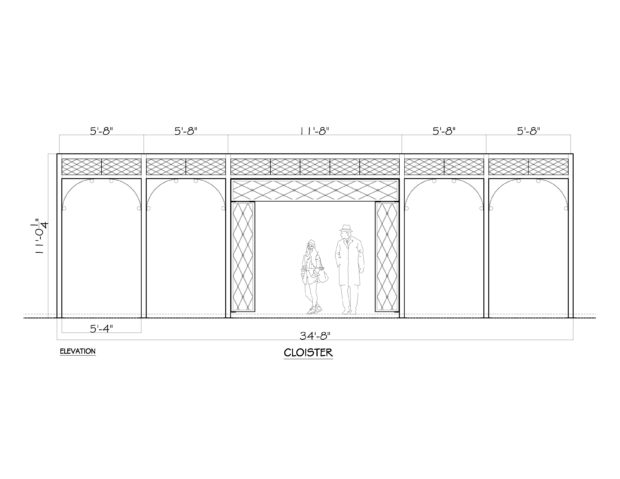

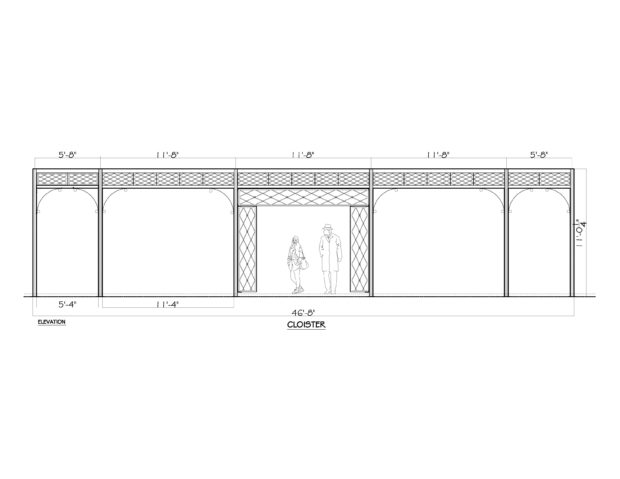

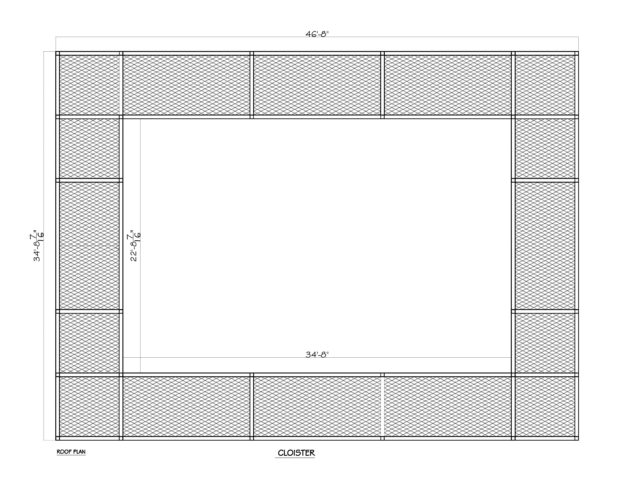

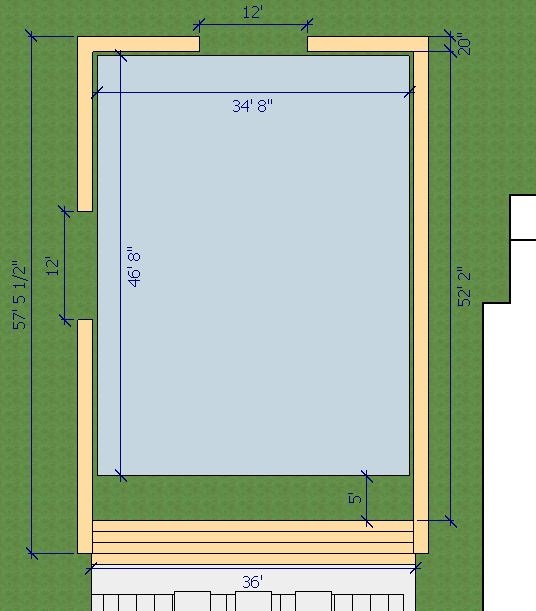

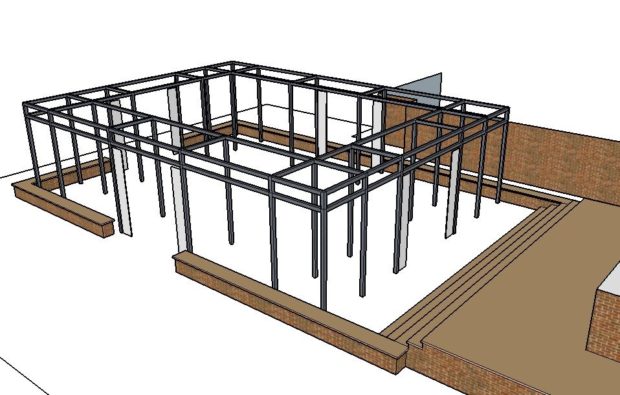

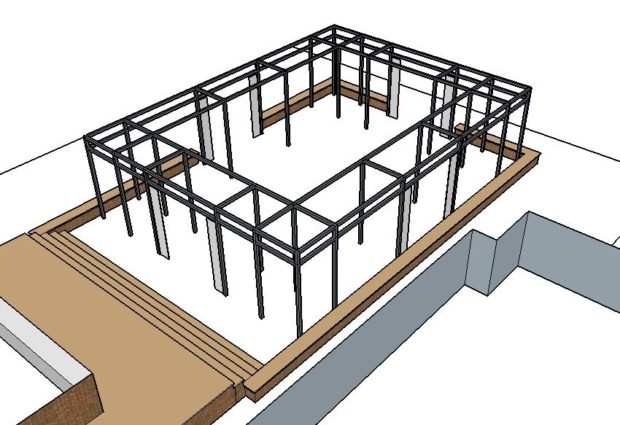

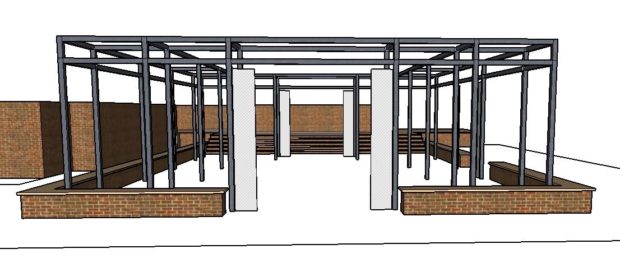

However, not every location for a pergola is accommodating to in ground plants. The south end of this deck is long ways away from any soil, and the location is very sunny. We needed a structure with the intrinsic ability to provide shade. A pergola that could provide a shaded area for dining and seating would be a welcome addition to the deck furnishings. The curving louver design was inspired by the art glass sheathing a waterfall next to the pool. Engineering this roof took time. Eventually, 28 individual fixed louver steel roof panels that could be dropped into a framework built in to the roof were fabricated. The structure is 32 feet long, and 14′ deep. The 11′ height of the structure matches the height of a horizontal frame set in a series of 6 large windows on the facade of the house. The columns and corner brackets are beefy, as the roof is heavy.

However, not every location for a pergola is accommodating to in ground plants. The south end of this deck is long ways away from any soil, and the location is very sunny. We needed a structure with the intrinsic ability to provide shade. A pergola that could provide a shaded area for dining and seating would be a welcome addition to the deck furnishings. The curving louver design was inspired by the art glass sheathing a waterfall next to the pool. Engineering this roof took time. Eventually, 28 individual fixed louver steel roof panels that could be dropped into a framework built in to the roof were fabricated. The structure is 32 feet long, and 14′ deep. The 11′ height of the structure matches the height of a horizontal frame set in a series of 6 large windows on the facade of the house. The columns and corner brackets are beefy, as the roof is heavy.

The pergola is tall enough that its roof does not interfere with the view out the picture windows. Nor does it restrict light coming in to those windows. It looks remarkably light and airy, considering it weighs 4500 pounds. The ipe deck is incredibly strong, but a pair of support beams traverse the underside of the deck to provide an additional level of support to the steel columns.

All of the roof panels are identical. But they cast different levels of shade depending on their orientation. Since the spring season is up next, and the intensity of sunlight at that time of year is subdued, the panels were placed to provide a more open shade from the south side. Being outdoors on a sunny spring day is one of the garden’s most memorable experiences.

All of the roof panels are identical. But they cast different levels of shade depending on their orientation. Since the spring season is up next, and the intensity of sunlight at that time of year is subdued, the panels were placed to provide a more open shade from the south side. Being outdoors on a sunny spring day is one of the garden’s most memorable experiences.

Viewed from the north side, the shade is more saturated. As the panels are dropped in, and held in place by the roof framing mechanism, the panels could be rotated to provide more shade from the south side later in the season. The panels could also be alternated one by one, or row by row, for other versions of shade. It would only take 2 people several hours to completely change the arrangement. The louver style means that warm air will be able to dissipate quickly.

Viewed from the northeast, it appears that the areas of sun and shade will be balanced.

From the north side, the shade cast will be much more pronounced. The sun is still low in the sky now, so it will be interesting to see what level of shade is provided once the sun is directly overhead. In any event, the pergola will go a long way towards providing a comfortable place to enjoy the outdoors.

From the north side, the shade cast will be much more pronounced. The sun is still low in the sky now, so it will be interesting to see what level of shade is provided once the sun is directly overhead. In any event, the pergola will go a long way towards providing a comfortable place to enjoy the outdoors.

Everyone’s interest and participation in the landscape is unique to them. I have come to have loads of respect for all forms that expression might take. On a practical level, it means trying to provide whatever direction it takes to get people outdoors. It also means cultivating empathy as an essential element of good design. What could happen next is not predictable, but I have had numerous instances over the years of a tentative interest in nature blossoming into a commitment to the health and well being of a piece of property. Or down the line a garden with which to teach their children how to grow vegetables and flowers. Or a new found love for spring flowering bulbs or fruit trees. It happens.

Everyone’s interest and participation in the landscape is unique to them. I have come to have loads of respect for all forms that expression might take. On a practical level, it means trying to provide whatever direction it takes to get people outdoors. It also means cultivating empathy as an essential element of good design. What could happen next is not predictable, but I have had numerous instances over the years of a tentative interest in nature blossoming into a commitment to the health and well being of a piece of property. Or down the line a garden with which to teach their children how to grow vegetables and flowers. Or a new found love for spring flowering bulbs or fruit trees. It happens.

There is a special personal satisfaction in having taken the design of a structure for the landscape to another level. Our head of design and engineering, Dan Moore, and his fabrication group of 6 do a terrific job of manufacturing our stock line of boxes, pots, fountains and ornament. They do an equally great job of engineering and fabricating something they have never made before. I think they like making those forays into the unknown. All they needed from me was the concept.

There is a special personal satisfaction in having taken the design of a structure for the landscape to another level. Our head of design and engineering, Dan Moore, and his fabrication group of 6 do a terrific job of manufacturing our stock line of boxes, pots, fountains and ornament. They do an equally great job of engineering and fabricating something they have never made before. I think they like making those forays into the unknown. All they needed from me was the concept.

It will scarcely be another month or two before this space will be humming with activity. The waterfall will be running and the pool will be open to the sky.The glass rails should be installed by Memorial Day. The furniture has arrived, and is in place; the outdoor grill is hooked up. I can easily imagine this space full of people enjoying a summer evening.

It will scarcely be another month or two before this space will be humming with activity. The waterfall will be running and the pool will be open to the sky.The glass rails should be installed by Memorial Day. The furniture has arrived, and is in place; the outdoor grill is hooked up. I can easily imagine this space full of people enjoying a summer evening.

The last part, as usual, will be the landscape. We will be ready to start that in a few weeks. Most of what we plant will be trees. A new generation tucked in to an existing old woodland.

The last part, as usual, will be the landscape. We will be ready to start that in a few weeks. Most of what we plant will be trees. A new generation tucked in to an existing old woodland.

Savoring this moment.