Big houses on very small properties-a given, in urban areas. A very small property that is hosting a very large house presents a special set of design considerations. The entire space is instantly visible. This makes it very difficult to create a sense of mystery, or discovery. There are few opportunities to create “rooms”, each with their own distinct atmosphere. There is a single view, and few options to generate other views. It is easy for a large structure placed in a small space to look uneasy or unsettled. Big buildings loom over small spaces. They block the light. They are the dominant landscape feature with a capital L.

Big houses on very small properties-a given, in urban areas. A very small property that is hosting a very large house presents a special set of design considerations. The entire space is instantly visible. This makes it very difficult to create a sense of mystery, or discovery. There are few opportunities to create “rooms”, each with their own distinct atmosphere. There is a single view, and few options to generate other views. It is easy for a large structure placed in a small space to look uneasy or unsettled. Big buildings loom over small spaces. They block the light. They are the dominant landscape feature with a capital L.

This particular property is very narrow. Critical to a successful landscape design is an assessment of how the house sits relative to the grade. This house is set very high, given that the client wanted window wells that would add light to the basement level rooms. This meant that a retaining wall and curb was necessary to create a driveway which is level. A driveway would necessarily be a big feature of this landscape. There is no room to make it a secondary feature. Given the stone on the house, I designed a concrete aggregate driveway with a stone curb. Why so much fuss over a utilitarian feature? When the driveway occupies a big part of the front yard landscape, that driveway needs to be functional and beautiful.

This particular property is very narrow. Critical to a successful landscape design is an assessment of how the house sits relative to the grade. This house is set very high, given that the client wanted window wells that would add light to the basement level rooms. This meant that a retaining wall and curb was necessary to create a driveway which is level. A driveway would necessarily be a big feature of this landscape. There is no room to make it a secondary feature. Given the stone on the house, I designed a concrete aggregate driveway with a stone curb. Why so much fuss over a utilitarian feature? When the driveway occupies a big part of the front yard landscape, that driveway needs to be functional and beautiful.

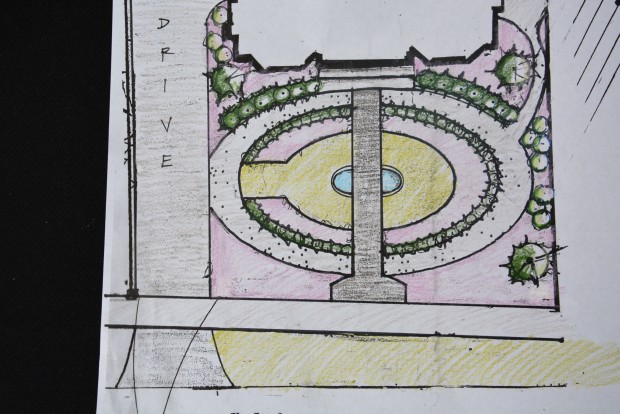

I like a front walk which begins at the sidewalk, and ends at the front door. That route may be direct, or meandering. It is also nice to have a walk from the driveway to the front door. This is a matter of convenience. The idea of pair of walkways in this small space seemed overpowering. I was thinking about a landscape which would be based on an ellipse. Much like a roundabout that enables traffic to flow, without stopping and starting. Though I am nervous approaching a roundabout, I find the process goes smoothly once I am in it. A gravel ellipse would touch the concrete aggregate drive such that a path from the drive to the front door would be visually unobtrusive.

I like a front walk which begins at the sidewalk, and ends at the front door. That route may be direct, or meandering. It is also nice to have a walk from the driveway to the front door. This is a matter of convenience. The idea of pair of walkways in this small space seemed overpowering. I was thinking about a landscape which would be based on an ellipse. Much like a roundabout that enables traffic to flow, without stopping and starting. Though I am nervous approaching a roundabout, I find the process goes smoothly once I am in it. A gravel ellipse would touch the concrete aggregate drive such that a path from the drive to the front door would be visually unobtrusive.

The gravel ellipse would be bordered on each side by garden. This would help to keep the gravel surface out of view from the street. The elliptical ring with the blue handled flat shovel pictured above would have a gravel surface. The innermost ring would be grass.

The property had been overrun with trucks over the course of the construction of the house. Given that the soil had been compacted to an extreme, we dug into it with pick axes and shovels. We would eventually work some compost into the soil, but I subscribe to the idea that plants will thrive if they like the existing planting conditions.

A pair of half elliptical fountains would be installed in the center of the garden. As much sculpture as fountain, they provide a focal point for the landscape. They could be planted with water plants, or not.

A pair of half elliptical fountains would be installed in the center of the garden. As much sculpture as fountain, they provide a focal point for the landscape. They could be planted with water plants, or not.

The big gestures are strongly horizontal, in contrast to the strong vertical lines of the house. Once the arcs of Hicks yews adjacent to the house have a chance to settle down and grow in, they will be maintained at a height below the ground floor windows. The gravel path from the drive to the front door is already invisible from the street. The yew, boxwood, and a pair of DeGroot Spires arborvitae will provide evergreen interest over the winter months.

The garden adjacent to the lawn features plants that grow three feet tall, or less. This garden will be dominated by peonies. Beautiful in bloom, the make compact and glossy leaved shrubs that look good all summer. The plants are spaced such to permit the additional of taller growing annual plants.

The garden adjacent to the lawn features plants that grow three feet tall, or less. This garden will be dominated by peonies. Beautiful in bloom, the make compact and glossy leaved shrubs that look good all summer. The plants are spaced such to permit the additional of taller growing annual plants.

There is a mix of plants. The outside garden will be taller, once it grows in. The Little Lime hydrangeas grow 4-5 feet tall, as will the roses. Russian sage and shasta daisies are bordered in the interior by stachys hummelo and Visions in Red astilbe. This garden will provide a sense of privacy and intimacy for the inner fountain garden. Adjacent to the sidewalk, a buffer of lamb’s ears and moss phlox. On the lot line, a single Vanderwolf’s flexible pine, a few magnolia stellata, and a grouping of fothergilla gardenii. A few lilacs, a favorite of the client, were placed where they would have room to grown. The lilacs are faced down with lespedeza. Euonymus “Moonlight” is planted behind the yews. A stand of “Goldner’s Bouquet” daylilies were planted on the south side of the house.

There is a mix of plants. The outside garden will be taller, once it grows in. The Little Lime hydrangeas grow 4-5 feet tall, as will the roses. Russian sage and shasta daisies are bordered in the interior by stachys hummelo and Visions in Red astilbe. This garden will provide a sense of privacy and intimacy for the inner fountain garden. Adjacent to the sidewalk, a buffer of lamb’s ears and moss phlox. On the lot line, a single Vanderwolf’s flexible pine, a few magnolia stellata, and a grouping of fothergilla gardenii. A few lilacs, a favorite of the client, were placed where they would have room to grown. The lilacs are faced down with lespedeza. Euonymus “Moonlight” is planted behind the yews. A stand of “Goldner’s Bouquet” daylilies were planted on the south side of the house.

Bordering the fountains, a frame of sedum John Creech will help to keep the lawn mower at bay. Interestingly enough, it is remarkably tolerant of the overspray from the fountains. This landscape has only one organizing idea. But rather than a beginning and an end, there is a roundabout.

Bordering the fountains, a frame of sedum John Creech will help to keep the lawn mower at bay. Interestingly enough, it is remarkably tolerant of the overspray from the fountains. This landscape has only one organizing idea. But rather than a beginning and an end, there is a roundabout.

A schematic landscape plan is a simple series of shapes that indicate what goes where, and how one travels from one place to another. If the landscape plan works well on a structural level, then the additional of the plants will bring a sculpture to life that is pleasing to the eye.

A schematic landscape plan is a simple series of shapes that indicate what goes where, and how one travels from one place to another. If the landscape plan works well on a structural level, then the additional of the plants will bring a sculpture to life that is pleasing to the eye.