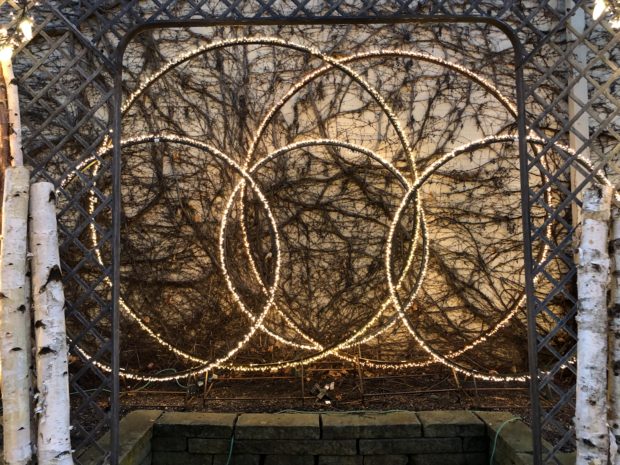

The centerpiece for a winter container will be all the better with the addition of light. After all, we have 12 hours of darkness this time of year. Nothing warms the winter landscape like lights glowing. Years ago it was a source of endless frustration, trying to arrange and suspend incandescent light strings in the air-so as to illuminate a twig based centerpiece. LED lighting devices are readily available now, making the job of getting winter containers to glow an easier one. Many of them so faithfully mimic a natural twig that they are invisible during the day. But no device is as beautiful, sculptural, effective, and simple as Rob’s light rings. A steel circle welded from steel channel is wound round with LED light strands that are attached every few inches with small zip ties. The rings have a base with 4 prongs that can be inserted into the soil of a container, or in the ground. The winter container pictured above was done by a good client of ours, whom we loosely coached on the finer points of our method of winter container construction. It did not take much time for him to grasp it all and run with it. This 54″ diameter bowl is home to a 5′ diameter light ring. The effect, even during the day, is spectacular. A light ring of this size needs additional ballast in the form of steel rebar, which is pounded down in to the soil, and attached to the light ring armature with concrete wire.

This picture reveals the look of the light ring from the side. We frequently make a separate foam form for the light ring, which will sit on top of the form that holds the greens. This makes for an easy installation of the light ring. Barely visible at the bottom is the triangular steel armature for the ring. This form is incredibly strong and stable.

This picture reveals the look of the light ring from the side. We frequently make a separate foam form for the light ring, which will sit on top of the form that holds the greens. This makes for an easy installation of the light ring. Barely visible at the bottom is the triangular steel armature for the ring. This form is incredibly strong and stable.

This particular construction features ball shaped lights attached to white faux branches. As the container has white faux berry stems, the lighted sticks are readily disguised. Making the lights in a container as invisible as possible during the day is a mark of thoughtful construction. Once this container is installed, no one will see the cords, transformers and electrical strips. What will shine the brightest is that all over glow.

The light ring is first and foremost a circle. That geometric form has no end of symbolic meanings, many of which have significance to gardeners. The lighted ring is a symbol of hope to me-the hope for the light at the end of the long tunnel coming up called winter. And the banishment of the winter dark. If none of those descriptions prove to be appealing to you, there is also the simple beauty of the form, and how it can organize and add visual and emotional heft to a winter pot. I am personally fond of an arrangement that keeps the complete circle visually intact. We either cut the greens below the lights on the ring, or install short pieces.

When Birdie adds greens to an arrangement, she is always watching the effect of her placement, and not her hands. This is a difficult concept to put in words. The hand will find the spot to insert a stem when the eye finds the spot where the stem should be. It takes imagination and confidence to work like this. The dry floral foam is very forgiving of a placement that needs to be changed or tuned up.

Though the twigs, picks light sticks look wonderfully chaotic, the process of assembling them so all the elements are evenly and brightly lit asks for a focused hand.

Though the twigs, picks light sticks look wonderfully chaotic, the process of assembling them so all the elements are evenly and brightly lit asks for a focused hand.

I can tell by the relaxed look on Birdie’s face that she is about to sign off on this pair of arrangements.

They look fiery in the shop. They will light the front door and portico of our client’s house in a dramatic and welcoming fashion.

The finished winter box has a sculptural presence, even during the day. It is evident in this picture that all of the lights in the ring will be clearly visible at night. Tougher to spot are the lighted white stems integrated into the dogwood branches. They will help to illuminate those branches at night.

pair of lighted pots

Snow flurries and a garland finishes the winter warm up.

See what I mean?

A client came in last week wearing a tee shirt that had the word BEAUTY printed across it. A few days later her Mom came in, wearing the same shirt. I have no idea as to the origin, intent or meaning of that word having been printed on that shirt. I did not ask. But it did set me to thinking about beauty. And how the pursuit and appreciation of it has been a life’s work, and the source of so much pleasure and satisfaction. Like many others, I came to be a gardener from an intense interest and fascination with the natural world. The visual drama of an emerging leaf, the impossibly intense blue color of a delphinium flower, the fragrance of a mock orange in bloom, the shape of an ancient beech tree-everything about the life of plants provides vigorous exercise and engagement to all of the senses. It is not at all unusual to know of a gardener swooning over this or that flower. So normal in my circle and probably yours. The beauty of nature provides a profound pleasure for the heart, hand, and soul, if you will.

A client came in last week wearing a tee shirt that had the word BEAUTY printed across it. A few days later her Mom came in, wearing the same shirt. I have no idea as to the origin, intent or meaning of that word having been printed on that shirt. I did not ask. But it did set me to thinking about beauty. And how the pursuit and appreciation of it has been a life’s work, and the source of so much pleasure and satisfaction. Like many others, I came to be a gardener from an intense interest and fascination with the natural world. The visual drama of an emerging leaf, the impossibly intense blue color of a delphinium flower, the fragrance of a mock orange in bloom, the shape of an ancient beech tree-everything about the life of plants provides vigorous exercise and engagement to all of the senses. It is not at all unusual to know of a gardener swooning over this or that flower. So normal in my circle and probably yours. The beauty of nature provides a profound pleasure for the heart, hand, and soul, if you will. A definitive explanation of what constitutes beauty is next to impossible, as it does not exist in a vacuum. A beauty designation is entirely arbitrary and fiercely personal. There is a unique relationship between the observer and the observed. What is seen and what is there to be seen. There are those gardeners who adore green flowers or spring ephemera, and those who wax poetic about hot pink peonies, yellow dahlias and red hibiscus. There are others that would be hard pressed to name a plant they don’t like, just as there are those who think that a beautiful landscape would by definition be confined to hellebores and beech trees. Zinnias are most beautiful to me in large part as they remind me of my Mom. Everyone has their own closely held ideas about what is beautiful.

A definitive explanation of what constitutes beauty is next to impossible, as it does not exist in a vacuum. A beauty designation is entirely arbitrary and fiercely personal. There is a unique relationship between the observer and the observed. What is seen and what is there to be seen. There are those gardeners who adore green flowers or spring ephemera, and those who wax poetic about hot pink peonies, yellow dahlias and red hibiscus. There are others that would be hard pressed to name a plant they don’t like, just as there are those who think that a beautiful landscape would by definition be confined to hellebores and beech trees. Zinnias are most beautiful to me in large part as they remind me of my Mom. Everyone has their own closely held ideas about what is beautiful. What constitutes beauty in a garden is a topic of endless discussion. Gardeners and designers of gardens fiercely debate the fine points, and acknowledge their common ground. I admire some gardens and landscapes more than others, as some are more beautiful to me than others. Whether it be plants, houses, landscapes, art, books, music, bridges or… garden pots, a need for beauty has always been an integral part of the human experience. It is as simple and as complex as that.

What constitutes beauty in a garden is a topic of endless discussion. Gardeners and designers of gardens fiercely debate the fine points, and acknowledge their common ground. I admire some gardens and landscapes more than others, as some are more beautiful to me than others. Whether it be plants, houses, landscapes, art, books, music, bridges or… garden pots, a need for beauty has always been an integral part of the human experience. It is as simple and as complex as that. It has been my good fortune over the years to come in contact with ornament for the garden of great beauty. I owe most of that exposure to Rob, who has been shopping and buying for Detroit Garden Works since before it opened in 1996. It is our 25th year in business this year. I find it remarkable that a modestly sized garden shop in the Midwest has not only survived for that long, it has prospered – buying and selling objects and plants of beauty for the garden. That beauty designation by Rob might include something smart and forward thinking. Some other item might be redolent of the earthy odor of history, sassy and off center, or strongly evocative of a farm garden. His is a very discerning eye, and his range of expertise in his field has been amassed over a long period of time. Opening the shop all those years ago was about wanting to share that aesthetic with other gardeners, and make beautiful garden ornament available to others. That is what we do – celebrate the beauty of the garden.

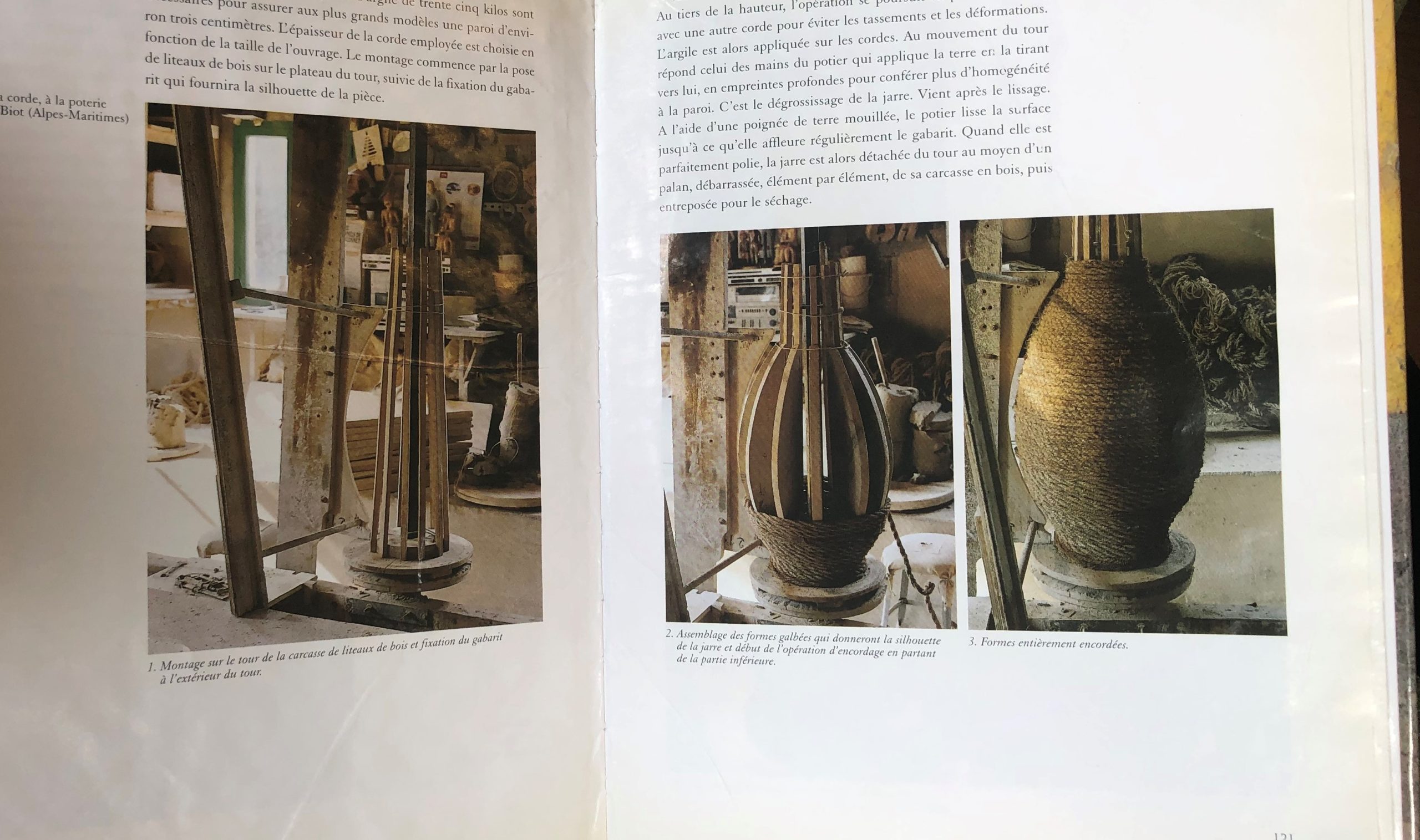

It has been my good fortune over the years to come in contact with ornament for the garden of great beauty. I owe most of that exposure to Rob, who has been shopping and buying for Detroit Garden Works since before it opened in 1996. It is our 25th year in business this year. I find it remarkable that a modestly sized garden shop in the Midwest has not only survived for that long, it has prospered – buying and selling objects and plants of beauty for the garden. That beauty designation by Rob might include something smart and forward thinking. Some other item might be redolent of the earthy odor of history, sassy and off center, or strongly evocative of a farm garden. His is a very discerning eye, and his range of expertise in his field has been amassed over a long period of time. Opening the shop all those years ago was about wanting to share that aesthetic with other gardeners, and make beautiful garden ornament available to others. That is what we do – celebrate the beauty of the garden. Which brings me to a discussion of these pots. They are of French manufacture. A poterie that has been in business since the late nineteenth century has evolved from a company making terra cotta roof and drain tiles to a fine art studio creating pots of great beauty for the garden. The poterie was built but 300 meters from their clay quarry. There is precious little about them that is not to like. The sculptural shapes are classically French. The designs date back centuries. Each pot is hand made, and signed by the artisan who made it.

Which brings me to a discussion of these pots. They are of French manufacture. A poterie that has been in business since the late nineteenth century has evolved from a company making terra cotta roof and drain tiles to a fine art studio creating pots of great beauty for the garden. The poterie was built but 300 meters from their clay quarry. There is precious little about them that is not to like. The sculptural shapes are classically French. The designs date back centuries. Each pot is hand made, and signed by the artisan who made it.

The contrasting surfaces are as appealing to the touch as they are to the eye.

The contrasting surfaces are as appealing to the touch as they are to the eye. This picture makes it clear that each pot is hand made. Each one of these olive jars is subtly different in shape and size than its neighbor.

This picture makes it clear that each pot is hand made. Each one of these olive jars is subtly different in shape and size than its neighbor. The pattern of the rope inside survives the glazing and firing process.

The pattern of the rope inside survives the glazing and firing process. The stamps

The stamps The collection of medium olive jars

The collection of medium olive jars

This is indeed an extraordinarily unusual and beautiful collection of pots.

This is indeed an extraordinarily unusual and beautiful collection of pots.