Detroit Garden Works hosted its first Garden Cruise to benefit the Greening of Detroit since 2019. I feel an intense satisfaction in being able to write that sentence. Perhaps some background for those readers who are not familiar with this event should come first. The Garden Cruise is a celebration of a lot of events. The landscape design that has been my life’s work. The extraordinary relationships created with clients culminating in the building of a landscape project. The selection and placement of beautiful and appropriate landscape ornament that physically centers and metaphorically organizes the landscape in question. And those steel boxes, benches, ornament, fountains and pergolas designed and manufactured in steel by my company, The Branch Studio. The wild shade garden portion of the landscape pictured above, which is part of the upcoming tour, features all of these things. It was designed and planted almost 10 years ago. The rod steel sphere fabricated at Branch Studio is fixed on top of a repurposed 19th century English stone lawn roller set on end – minus its steel armature – as a rather contemporary pedestal. That piece was sourced and purchased in England by Rob Yedinak, and shipped to Detroit Garden Works and offered for sale. The wild garden features shade plants that beautifully represent and thrive in Michigan-so hellebores, sweet woodruff, pulmonaria, brunnera, hamamelis-and hemlocks. The big old spruce had seen better days, but why remove plants of such majestic scale and presence?

These clients are extraordinary people. They have diverse interests, but to the last they are united in their love of this house which is turning 100 years old, their love of nature and the natural world, and their commitment to preservation and restoration. The bricks and limestone slabs were part of a wall in such disrepair that it had to come down and be rebuilt. Those stone and brick elements featured in the walk above were the original wall materials they felt were too beautiful to throw away. They asked me to design something around them. We call this path from the back yard to the front yard “the history walk”. There was story telling. History and artistry. In all my years of designing and installing landscapes, this photograph of my client in his surgical scrubs touring his garden late in the day is one of my favorites. Gardens are good for people.

They also have a big love for entertaining outdoors in the summer. I drew a 20′ diameter circle on the site plan, and wrote the word POOL in the center. Ha! That ignited a firestorm of discussion, most of which had to do with not wanting a round pool. I was able to persuade them that round entertaining spaces are so friendly. And that it would fit handsomely in their oddly shaped lot. I was able to persuade them, once the shock of the suggestion had faded. A final design featuring the change of grade between the house and the rear lot line looked exactly like who it was for.

That is an essential part of a successful landscape design – a relationship that enables work that looks like it belongs to the client and their property. This landscape has been on the tour before, but the way in which it is evolving and maturing makes it well worth another visit.

These clients have invested 25 years in the landscape and gardens on their 7 acre property. They went so far as to purchase the house next door, as it would complete and make whole a natural feature of the land. What an extraordinary thing to do! The property is packed with gorgeous mature trees – some usual fare, and some rarely seen outside of an arboretum.

In recent years I have been involved in the landscape design of those areas adjacent to both the main house and the getaway house. This portion of the landscape has a distinctive contemporary feel that is quite formal. The allee of columnar hornbeams pictured above is at the beginning of a very unusual trimming protocol. The outsides of the trees will be pruned flat, and the interior will be a celebration of the natural arching branches of these trees.

Adjacent and perpendicular to the broad gravel pathway which connects the main house to the other is a 50′ diameter circle of liriope spicata. The texture and mass generated by this single plant is stunning. On a breezy day, it is constantly in motion. What is perhaps the most amazing is that these clients maintain virtually the whole of their property themselves. I am not sure how many containers they have filled with seasonal plants, but that number is big.

In additional to small seating areas sprinkled throughout the gardens, there are plenty of places near the house to leisurely sit and enjoy the out of doors. They have devoted considerable effort to providing a large terrace, pergolas, and furnishings to host friends and family comfortably for meals, parties and celebrations. Plan to spend some time exploring this landscape.

My landscape and gardens have been on the Garden tour every year since they began in 2008. A visit was mostly about how plants had grown. The only substantial change from year to year was the container plantings. This year is not so much different, except for the deck and fountain garden.

I do have new furniture, and a mix of of pots. French glazed pots from Terre Albine so enchanted me that I had to have some at home. All of these particular pots were broken from a series of unrelated mishaps. One of the fabricators at the Branch Studio was able to piece them all back together. I like that these beautiful pots still have a place in a garden, and I love them in my garden.

I am not posting any pictures of the fountain garden. Better that you see it in person. It is completely and shockingly different than it once was. Everything has a life span, including a landscape and garden. This part of my landscape has only been in 2 years.

I am not posting any pictures of the fountain garden. Better that you see it in person. It is completely and shockingly different than it once was. Everything has a life span, including a landscape and garden. This part of my landscape has only been in 2 years.

This client has always had an interest in plants and flowers, but he has a fairly new and more substantial involvement. I was able to redo areas of the landscape to feature more ornamental plants and containers. He is watering his pots when they need it, and keeping his eye on all of the plants.

He is thoroughly enjoying what pleasure the outdoors can provide to people.

A large scale pool which is an entertainment focal point for his family and friends now has the ornamental gardens to go with. A mature hedge of Green Giant arborvitae provides a gorgeous backdrop and lots of privacy to the pool deck. In the immediate foreground is a series of three steel planter boxes fabricated at Branch. A section of a boxwood hedge was removed and planted elsewhere in favor of a seasonal flower display.

This landscape features a formal front yard composed of masses of spherically pruned Green Gem boxwood, boxed smaller scale Green Gems, and Venus dogwoods. A hedge of limelight hydrangeas encloses it all. This pattern of planting encloses a spacious drive court. The house sits high on a rather steep hill, so parking near the house was a landscape priority.

The back yard with literally no flat space has been transformed by a 3200 square foot wood deck made from Ipe. The far end of this deck is 11 feet above the existing grade. Inset in the deck is a three sided infinity edge pool and waterfall. At the far end, a large scale pergola designed with louvered roof panels for shade by Branch Studio provides a shady spot for lounging and dining. The surrounding landscape is informal and lush.

I do hope as many of you as possible who are reading will attend this Garden Cruise on July 23, 2023 from 9am to 4:30pm, and the cocktails and pizza dinner reception to be held at Detroit Garden Works afterwards. So many have asked me to sponsor a tour again, and to write again. I am doing both. It will be an excellent tour well worth the time of any person for whom the garden is a way of life.

All of the proceeds of the ticket sales – 40.00 for the cruise, and 55.00 for the cruise and reception – go to benefit the programs of the Greening of Detroit – an organization whose work I think is crucially important to the City of Detroit. For further information www.thegardencruise.org Tickets can be purchased over the phone or in person at Detroit Garden Works. 248 335 8057.

This picture reveals the look of the light ring from the side. We frequently make a separate foam form for the light ring, which will sit on top of the form that holds the greens. This makes for an easy installation of the light ring. Barely visible at the bottom is the triangular steel armature for the ring. This form is incredibly strong and stable.

This picture reveals the look of the light ring from the side. We frequently make a separate foam form for the light ring, which will sit on top of the form that holds the greens. This makes for an easy installation of the light ring. Barely visible at the bottom is the triangular steel armature for the ring. This form is incredibly strong and stable.

Though the twigs, picks light sticks look wonderfully chaotic, the process of assembling them so all the elements are evenly and brightly lit asks for a focused hand.

Though the twigs, picks light sticks look wonderfully chaotic, the process of assembling them so all the elements are evenly and brightly lit asks for a focused hand.

Ordering materials for containers on line or from a print catalogue is incredibly difficult. I have tried it, and I have had plenty of materials delivered that were not great. As in, did I buy this, no kidding??? I have tried to avoid shopping on line. I shopped the holiday and winter materials in person with Rob for 5 or 6 years. I liked being able to hold a pick in my hand. I could see the color. I could assess what its durability would be in a container. I could see the finished height-and the width. I could see how it would read. I could see how the shape, mass, and color would work with other elements under consideration. I could see what picks would be investment caliber, and which would be a one season fling. My shopping days are over now. I am happy to turn over the shopping for the winter season materials to Rob and Sunne. I have confidence that their choices will work for a wide range of my projects. And I respect and am intrigued by what materials they chooses from their own individual aesthetic. It is up to me to put what they buy together in such a way that my clients feel their taste is represented. If you are thinking that my design for holiday and winter container arrangements is fueled by beautiful materials- you are right.

Ordering materials for containers on line or from a print catalogue is incredibly difficult. I have tried it, and I have had plenty of materials delivered that were not great. As in, did I buy this, no kidding??? I have tried to avoid shopping on line. I shopped the holiday and winter materials in person with Rob for 5 or 6 years. I liked being able to hold a pick in my hand. I could see the color. I could assess what its durability would be in a container. I could see the finished height-and the width. I could see how it would read. I could see how the shape, mass, and color would work with other elements under consideration. I could see what picks would be investment caliber, and which would be a one season fling. My shopping days are over now. I am happy to turn over the shopping for the winter season materials to Rob and Sunne. I have confidence that their choices will work for a wide range of my projects. And I respect and am intrigued by what materials they chooses from their own individual aesthetic. It is up to me to put what they buy together in such a way that my clients feel their taste is represented. If you are thinking that my design for holiday and winter container arrangements is fueled by beautiful materials- you are right.

A client came in last week wearing a tee shirt that had the word BEAUTY printed across it. A few days later her Mom came in, wearing the same shirt. I have no idea as to the origin, intent or meaning of that word having been printed on that shirt. I did not ask. But it did set me to thinking about beauty. And how the pursuit and appreciation of it has been a life’s work, and the source of so much pleasure and satisfaction. Like many others, I came to be a gardener from an intense interest and fascination with the natural world. The visual drama of an emerging leaf, the impossibly intense blue color of a delphinium flower, the fragrance of a mock orange in bloom, the shape of an ancient beech tree-everything about the life of plants provides vigorous exercise and engagement to all of the senses. It is not at all unusual to know of a gardener swooning over this or that flower. So normal in my circle and probably yours. The beauty of nature provides a profound pleasure for the heart, hand, and soul, if you will.

A client came in last week wearing a tee shirt that had the word BEAUTY printed across it. A few days later her Mom came in, wearing the same shirt. I have no idea as to the origin, intent or meaning of that word having been printed on that shirt. I did not ask. But it did set me to thinking about beauty. And how the pursuit and appreciation of it has been a life’s work, and the source of so much pleasure and satisfaction. Like many others, I came to be a gardener from an intense interest and fascination with the natural world. The visual drama of an emerging leaf, the impossibly intense blue color of a delphinium flower, the fragrance of a mock orange in bloom, the shape of an ancient beech tree-everything about the life of plants provides vigorous exercise and engagement to all of the senses. It is not at all unusual to know of a gardener swooning over this or that flower. So normal in my circle and probably yours. The beauty of nature provides a profound pleasure for the heart, hand, and soul, if you will. A definitive explanation of what constitutes beauty is next to impossible, as it does not exist in a vacuum. A beauty designation is entirely arbitrary and fiercely personal. There is a unique relationship between the observer and the observed. What is seen and what is there to be seen. There are those gardeners who adore green flowers or spring ephemera, and those who wax poetic about hot pink peonies, yellow dahlias and red hibiscus. There are others that would be hard pressed to name a plant they don’t like, just as there are those who think that a beautiful landscape would by definition be confined to hellebores and beech trees. Zinnias are most beautiful to me in large part as they remind me of my Mom. Everyone has their own closely held ideas about what is beautiful.

A definitive explanation of what constitutes beauty is next to impossible, as it does not exist in a vacuum. A beauty designation is entirely arbitrary and fiercely personal. There is a unique relationship between the observer and the observed. What is seen and what is there to be seen. There are those gardeners who adore green flowers or spring ephemera, and those who wax poetic about hot pink peonies, yellow dahlias and red hibiscus. There are others that would be hard pressed to name a plant they don’t like, just as there are those who think that a beautiful landscape would by definition be confined to hellebores and beech trees. Zinnias are most beautiful to me in large part as they remind me of my Mom. Everyone has their own closely held ideas about what is beautiful. What constitutes beauty in a garden is a topic of endless discussion. Gardeners and designers of gardens fiercely debate the fine points, and acknowledge their common ground. I admire some gardens and landscapes more than others, as some are more beautiful to me than others. Whether it be plants, houses, landscapes, art, books, music, bridges or… garden pots, a need for beauty has always been an integral part of the human experience. It is as simple and as complex as that.

What constitutes beauty in a garden is a topic of endless discussion. Gardeners and designers of gardens fiercely debate the fine points, and acknowledge their common ground. I admire some gardens and landscapes more than others, as some are more beautiful to me than others. Whether it be plants, houses, landscapes, art, books, music, bridges or… garden pots, a need for beauty has always been an integral part of the human experience. It is as simple and as complex as that. It has been my good fortune over the years to come in contact with ornament for the garden of great beauty. I owe most of that exposure to Rob, who has been shopping and buying for Detroit Garden Works since before it opened in 1996. It is our 25th year in business this year. I find it remarkable that a modestly sized garden shop in the Midwest has not only survived for that long, it has prospered – buying and selling objects and plants of beauty for the garden. That beauty designation by Rob might include something smart and forward thinking. Some other item might be redolent of the earthy odor of history, sassy and off center, or strongly evocative of a farm garden. His is a very discerning eye, and his range of expertise in his field has been amassed over a long period of time. Opening the shop all those years ago was about wanting to share that aesthetic with other gardeners, and make beautiful garden ornament available to others. That is what we do – celebrate the beauty of the garden.

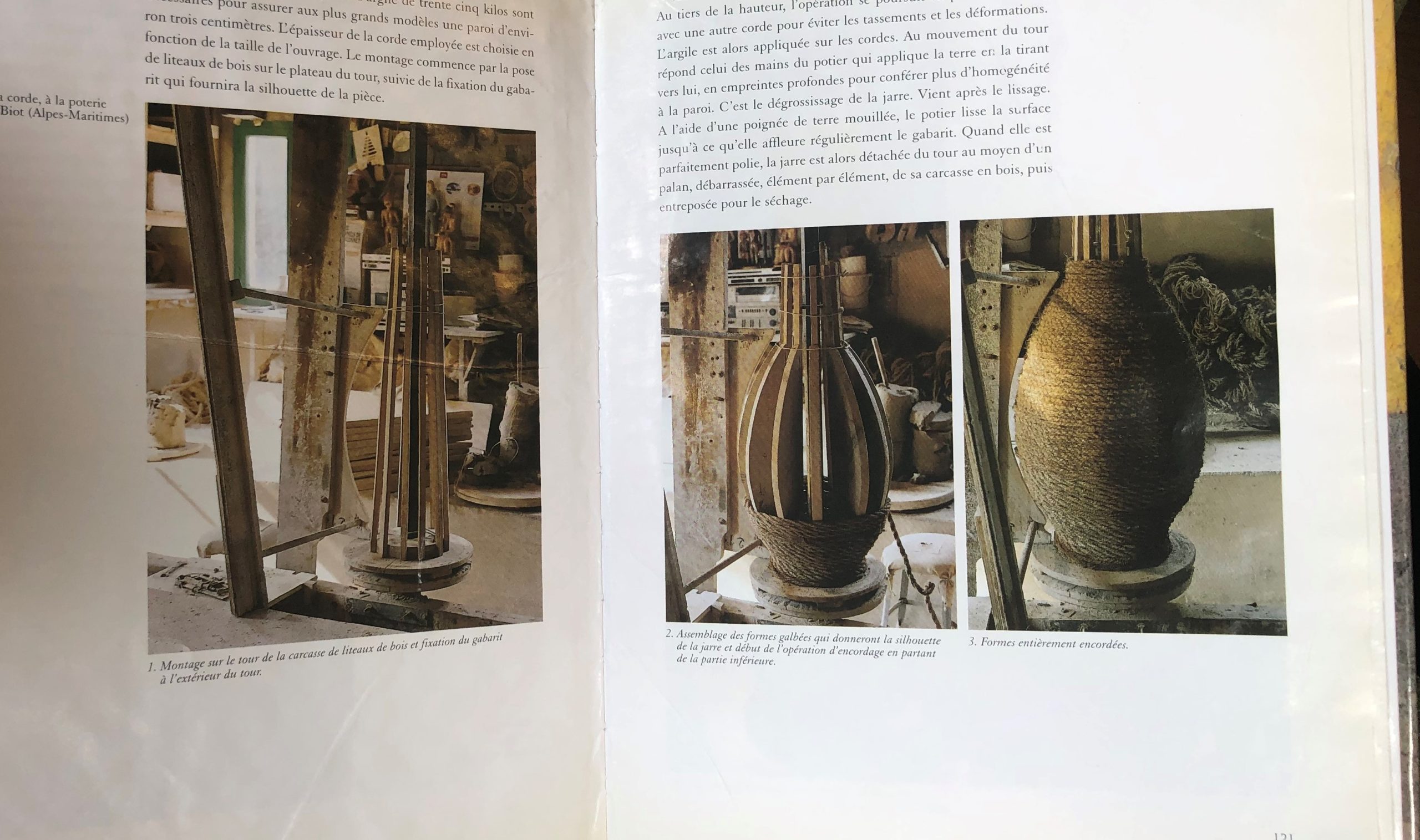

It has been my good fortune over the years to come in contact with ornament for the garden of great beauty. I owe most of that exposure to Rob, who has been shopping and buying for Detroit Garden Works since before it opened in 1996. It is our 25th year in business this year. I find it remarkable that a modestly sized garden shop in the Midwest has not only survived for that long, it has prospered – buying and selling objects and plants of beauty for the garden. That beauty designation by Rob might include something smart and forward thinking. Some other item might be redolent of the earthy odor of history, sassy and off center, or strongly evocative of a farm garden. His is a very discerning eye, and his range of expertise in his field has been amassed over a long period of time. Opening the shop all those years ago was about wanting to share that aesthetic with other gardeners, and make beautiful garden ornament available to others. That is what we do – celebrate the beauty of the garden. Which brings me to a discussion of these pots. They are of French manufacture. A poterie that has been in business since the late nineteenth century has evolved from a company making terra cotta roof and drain tiles to a fine art studio creating pots of great beauty for the garden. The poterie was built but 300 meters from their clay quarry. There is precious little about them that is not to like. The sculptural shapes are classically French. The designs date back centuries. Each pot is hand made, and signed by the artisan who made it.

Which brings me to a discussion of these pots. They are of French manufacture. A poterie that has been in business since the late nineteenth century has evolved from a company making terra cotta roof and drain tiles to a fine art studio creating pots of great beauty for the garden. The poterie was built but 300 meters from their clay quarry. There is precious little about them that is not to like. The sculptural shapes are classically French. The designs date back centuries. Each pot is hand made, and signed by the artisan who made it.

The contrasting surfaces are as appealing to the touch as they are to the eye.

The contrasting surfaces are as appealing to the touch as they are to the eye. This picture makes it clear that each pot is hand made. Each one of these olive jars is subtly different in shape and size than its neighbor.

This picture makes it clear that each pot is hand made. Each one of these olive jars is subtly different in shape and size than its neighbor. The pattern of the rope inside survives the glazing and firing process.

The pattern of the rope inside survives the glazing and firing process. The stamps

The stamps The collection of medium olive jars

The collection of medium olive jars

This is indeed an extraordinarily unusual and beautiful collection of pots.

This is indeed an extraordinarily unusual and beautiful collection of pots.