Winter at the Branch Studio is a gritty affair. The building is too large and drafty to heat to any decent level. Everyone over there lives in their insulated carhardts, boots and leather gloves-amongst a whole host of other gear. The wind makes the doors rattle like crazy. Enter if you dare. There is nothing romantic about manufacturing, but there is a special beauty in the making that goes on over there. A group of men who take extraordinary care in their fabrication. Beyond the din, dirt and sparks of a fleet of welders in use, there is a collective heart beating strong. These guys weld cold rolled and pickled steel. It is not an occupation for the faint of heart. Steel bends for no man. That said, my group at Branch works hard to make steel friendly to the landscape.

Winter at the Branch Studio is a gritty affair. The building is too large and drafty to heat to any decent level. Everyone over there lives in their insulated carhardts, boots and leather gloves-amongst a whole host of other gear. The wind makes the doors rattle like crazy. Enter if you dare. There is nothing romantic about manufacturing, but there is a special beauty in the making that goes on over there. A group of men who take extraordinary care in their fabrication. Beyond the din, dirt and sparks of a fleet of welders in use, there is a collective heart beating strong. These guys weld cold rolled and pickled steel. It is not an occupation for the faint of heart. Steel bends for no man. That said, my group at Branch works hard to make steel friendly to the landscape.

Containers, fountains and garden ornament made at Branch comes straight out of the manufacturing heritage every bred in Detroit fabricator is heir to. This means garden ornament designed and fabricated to last. Boxes and fountains that can withstand anything nature decides to dish out. Everything at Branch is hand made, and rock solid. The finish we have developed is a patina much like lead. The stainless steel Branch tags that are attached to everything we make identifies our work, and attests to its longevity. The Branch Studio is the youngest of my companies-just 11 years old this year. The work however speaks to a maturity of which I am proud.

Containers, fountains and garden ornament made at Branch comes straight out of the manufacturing heritage every bred in Detroit fabricator is heir to. This means garden ornament designed and fabricated to last. Boxes and fountains that can withstand anything nature decides to dish out. Everything at Branch is hand made, and rock solid. The finish we have developed is a patina much like lead. The stainless steel Branch tags that are attached to everything we make identifies our work, and attests to its longevity. The Branch Studio is the youngest of my companies-just 11 years old this year. The work however speaks to a maturity of which I am proud.

The winter is the time we make all of our stock boxes, fountains and pergolas, in anticipation of the spring season. But we also take time to design and fabricate new things. I have been after Buck to fabricate a fountain of a design very different than our usual classically based garden ornament for at least 2 years. He was slow to cotton to the idea, but in January I could talk of nothing else. He finally heard me. A Branch fountain got off the ground.

The winter is the time we make all of our stock boxes, fountains and pergolas, in anticipation of the spring season. But we also take time to design and fabricate new things. I have been after Buck to fabricate a fountain of a design very different than our usual classically based garden ornament for at least 2 years. He was slow to cotton to the idea, but in January I could talk of nothing else. He finally heard me. A Branch fountain got off the ground.

This fountain is comprised of almost a mile of steel rods, and weighs 3500 pounds. On the outside, the fountain measures 5′ wide by 9′ long. The bottom of the fountain was built as a torsion box, the weight was so great. Buck held more than a few confabs with his group regarding visual density and texture. The design called for a certain density, that would be satisfied differently, depending on the diameter of the rods. The texture needed to be congested, but loose. A good friend remarked upon seeing the finished fountain that she was intrigued that a material so hard and heavy could be made to look so soft.

This fountain is comprised of almost a mile of steel rods, and weighs 3500 pounds. On the outside, the fountain measures 5′ wide by 9′ long. The bottom of the fountain was built as a torsion box, the weight was so great. Buck held more than a few confabs with his group regarding visual density and texture. The design called for a certain density, that would be satisfied differently, depending on the diameter of the rods. The texture needed to be congested, but loose. A good friend remarked upon seeing the finished fountain that she was intrigued that a material so hard and heavy could be made to look so soft.

Once the shell of this fountain was built, my conversation centered on the magic that that can be created by the human hand. Every hand is distinctive, like a signature. I was after a group signature. A show of hands. Everyone welding on this project changed positions every hour. No matter what view you take, the look is about community of hands-homogeneous.

Once the shell of this fountain was built, my conversation centered on the magic that that can be created by the human hand. Every hand is distinctive, like a signature. I was after a group signature. A show of hands. Everyone welding on this project changed positions every hour. No matter what view you take, the look is about community of hands-homogeneous.

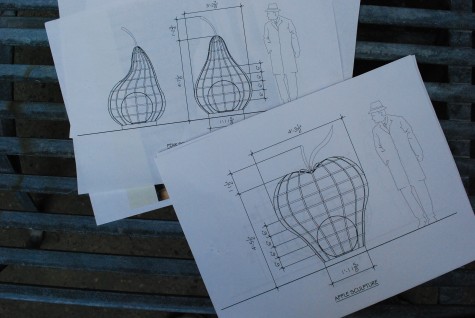

The texture is created from 8 sizes of steel rods, from 3/16 inch, up to 3/4 inch. The length, size, and placement of each individual rod was a decision that had to be made, hour after hour, and week after week. This was their first outing without a fistful of CAD drawings and clear specifications. We were building a fountain yes, but we decided to broach the topic of sculpture.

The texture is created from 8 sizes of steel rods, from 3/16 inch, up to 3/4 inch. The length, size, and placement of each individual rod was a decision that had to be made, hour after hour, and week after week. This was their first outing without a fistful of CAD drawings and clear specifications. We were building a fountain yes, but we decided to broach the topic of sculpture.

Stepping outside any routine is about taking chances. Taking a chance can be more than one bargained for. But a result that is more than one bargains for is well worth the effort. My welding group at Branch stepped right up to the challenge posed by this design, and dove in. Their collective signature is all over this fountain.

Stepping outside any routine is about taking chances. Taking a chance can be more than one bargained for. But a result that is more than one bargains for is well worth the effort. My welding group at Branch stepped right up to the challenge posed by this design, and dove in. Their collective signature is all over this fountain.

The signature of every artisan at Branch is represented in this fountain. I can read the moves, and I can see the names.

The signature of every artisan at Branch is represented in this fountain. I can read the moves, and I can see the names.

The act of creating is a thrill like no other. A painting. A quilt. A symphony. A poem. A dress. An event. A car. A necklace. A company. A garden. Branch of course is interested to be a sculptural part of the landscape.

The act of creating is a thrill like no other. A painting. A quilt. A symphony. A poem. A dress. An event. A car. A necklace. A company. A garden. Branch of course is interested to be a sculptural part of the landscape.

The Branch fountain is a sculpture around which a garden could be forged.

The Branch fountain is a sculpture around which a garden could be forged.

This is the news from the Branch Studio.

This is the news from the Branch Studio.