Rob recently posted a photograph to his instagram of the urns and planter boxes in the front of my house. You can see that photo here: Rob’s instagram page A reader asked for more detail on those urns, and the story behind them. You can barely see one of the four in the right hand side of the picture above, just about buried in petunias. As it happens, there is a story behind those pots, that dates back 88 years.

Rob recently posted a photograph to his instagram of the urns and planter boxes in the front of my house. You can see that photo here: Rob’s instagram page A reader asked for more detail on those urns, and the story behind them. You can barely see one of the four in the right hand side of the picture above, just about buried in petunias. As it happens, there is a story behind those pots, that dates back 88 years.

Some 23 years ago, my good friend Frech knew I was looking to move closer to a building and property that I had purchased that would become Detroit Garden Works. He called and insisted that I go look at a house for sale just 2 miles from the shop. I made an appointment with the sales broker, and arrived 20 minutes early. I had a lot of time to look at those cast iron urns. I had never seen any urn quite like them. There were two at the front door, and two more at the driveway entrance. I fell for them head over heels. I am embarrassed to say that I had decided to try to buy the house before I ever set a foot inside. I loved those pots.

Some 23 years ago, my good friend Frech knew I was looking to move closer to a building and property that I had purchased that would become Detroit Garden Works. He called and insisted that I go look at a house for sale just 2 miles from the shop. I made an appointment with the sales broker, and arrived 20 minutes early. I had a lot of time to look at those cast iron urns. I had never seen any urn quite like them. There were two at the front door, and two more at the driveway entrance. I fell for them head over heels. I am embarrassed to say that I had decided to try to buy the house before I ever set a foot inside. I loved those pots.

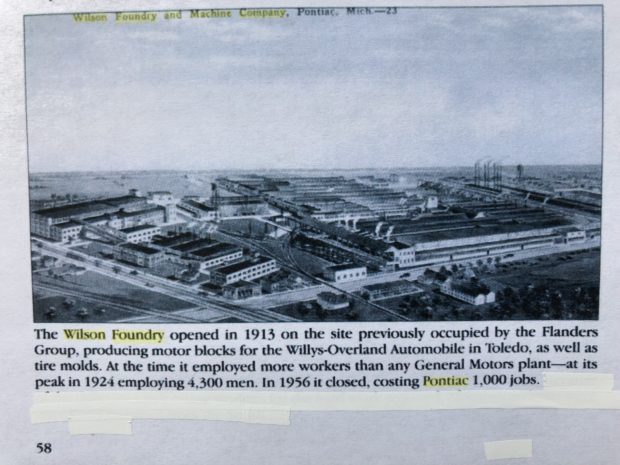

I have spent some time since then, researching them, as I have never seen any garden urns quite like them. There was a long ways to go from the inquiry to an answer. I knew from the seller that the house was built by the owner of a foundry in Pontiac, which would eventually become a foundry for General Motors. I was able to determine that the Wilson Foundry and Machine Co, was established by A. R. Wilson. He was actually a huge help to Willys, helping to pull them through an economic down turn that threatened to bankrupt the company. He was a manufacturer amply endowed with vision.

I have spent some time since then, researching them, as I have never seen any garden urns quite like them. There was a long ways to go from the inquiry to an answer. I knew from the seller that the house was built by the owner of a foundry in Pontiac, which would eventually become a foundry for General Motors. I was able to determine that the Wilson Foundry and Machine Co, was established by A. R. Wilson. He was actually a huge help to Willys, helping to pull them through an economic down turn that threatened to bankrupt the company. He was a manufacturer amply endowed with vision.

His foundry would become the largest major supplier to Willys International, of cast iron engine blocks and parts. None of their parts were welded together from individual pieces of steel. Each part was cast from molten steel poured into a sand mold. That process is complicated, and astonishing.

His foundry would become the largest major supplier to Willys International, of cast iron engine blocks and parts. None of their parts were welded together from individual pieces of steel. Each part was cast from molten steel poured into a sand mold. That process is complicated, and astonishing.

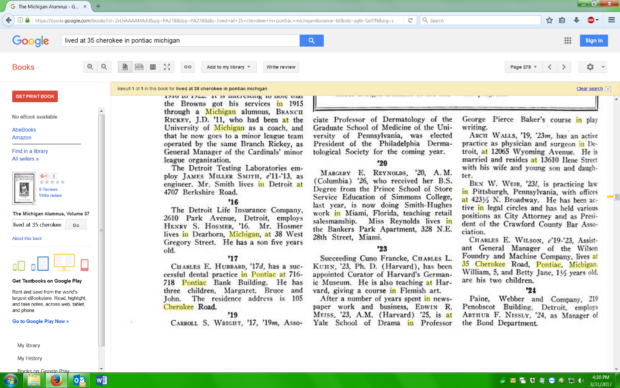

Though I am not a historian, I did find that Mr. Wilson had a son, Charles E. Wilson, who was the assistant general manager of the Wilson Foundry and Machine Co. A University Of Michigan publication from the 1920’s, part of which is pictured above, confirmed that a Charles E Wilson, who graduated in the U of M class of 1923, at one time lived in my house. I purchased my house from two men who had done an incredible job of keeping up a house of great age. They did give me lots of materials they had collected on the history of the house, all of which were lost during a flood in my basement. But I do remember them telling me that the father, A.R. Wilson, built my house as a wedding gift to his son and daughter in law. The house is solid concrete block, finished in brick, copper and limestone. The construction was commercial grade. Though I live but a block off a major roadway, my house is quiet inside. It stays cool well into the summer, and stays warm well into the winter.

Though I am not a historian, I did find that Mr. Wilson had a son, Charles E. Wilson, who was the assistant general manager of the Wilson Foundry and Machine Co. A University Of Michigan publication from the 1920’s, part of which is pictured above, confirmed that a Charles E Wilson, who graduated in the U of M class of 1923, at one time lived in my house. I purchased my house from two men who had done an incredible job of keeping up a house of great age. They did give me lots of materials they had collected on the history of the house, all of which were lost during a flood in my basement. But I do remember them telling me that the father, A.R. Wilson, built my house as a wedding gift to his son and daughter in law. The house is solid concrete block, finished in brick, copper and limestone. The construction was commercial grade. Though I live but a block off a major roadway, my house is quiet inside. It stays cool well into the summer, and stays warm well into the winter.

The old paint on the pots was peeling, and faded. I decided to have Buck media blast them, to remove all of the paint. I was shocked to see that the bare steel was gray. Raw cold rolled steel is dark. Literature from the Wilson Foundry speaks of their castings being “gray metal”. Once I saw them in their stripped state, I knew that the Wilson Foundry designed and cast them specifically for his son’s home. I have searched high and low for any cast iron urn that resembles mine. I have never found anything like them. They are incredibly thick cast iron, and incredibly heavy.

The old paint on the pots was peeling, and faded. I decided to have Buck media blast them, to remove all of the paint. I was shocked to see that the bare steel was gray. Raw cold rolled steel is dark. Literature from the Wilson Foundry speaks of their castings being “gray metal”. Once I saw them in their stripped state, I knew that the Wilson Foundry designed and cast them specifically for his son’s home. I have searched high and low for any cast iron urn that resembles mine. I have never found anything like them. They are incredibly thick cast iron, and incredibly heavy.

Once the countless layers of old paint came off the urns, the stamp of Wilson Foundry and Machine Co was easy to see. Of course I believe that my four pots were more than likely the only garden urns ever produced at this foundry devoted to engine blocks for Jeeps. The urns and the planter boxes were powder coated 30% gloss black. The finish should last a very long time.

Once the countless layers of old paint came off the urns, the stamp of Wilson Foundry and Machine Co was easy to see. Of course I believe that my four pots were more than likely the only garden urns ever produced at this foundry devoted to engine blocks for Jeeps. The urns and the planter boxes were powder coated 30% gloss black. The finish should last a very long time.

My house is registered with the US data base of historic homes. But it was pure instinct on my part to speak for the house that was a home for these urns. 24 years later, I am happy for my decision. The Branch Studio made 8″ tall square steel bases for the urns, so they would sit up and stand out in the front yard landscape. They also made me almost 60 feet of planter boxes in between those urns in which I could plant whatever I fancy in all of the seasons. The assembly is a container designer’s dream come true.

My house is registered with the US data base of historic homes. But it was pure instinct on my part to speak for the house that was a home for these urns. 24 years later, I am happy for my decision. The Branch Studio made 8″ tall square steel bases for the urns, so they would sit up and stand out in the front yard landscape. They also made me almost 60 feet of planter boxes in between those urns in which I could plant whatever I fancy in all of the seasons. The assembly is a container designer’s dream come true.

The boxy Branch base was set under the hexagonal urn base, and on top of the original brick and limestone pillars. A few weeks ago removed an old scraggly hedge of taxus densiformis, so my planter boxes could be seen from the street.

The boxy Branch base was set under the hexagonal urn base, and on top of the original brick and limestone pillars. A few weeks ago removed an old scraggly hedge of taxus densiformis, so my planter boxes could be seen from the street.

In place of the yews is a short but deep hedge of Green Gem boxwood. A lower layer of landscape is so much better in front of the planter boxes. I am so pleased that those gorgeous urns have become a major feature of my front yard landscape.

In place of the yews is a short but deep hedge of Green Gem boxwood. A lower layer of landscape is so much better in front of the planter boxes. I am so pleased that those gorgeous urns have become a major feature of my front yard landscape.

The urns float just above the old boxwood flanking the front walk. I like the look. The boxes are planted with nicotiana mutabilis, nicotiana alata lime and petunias. No fancy plants – just a fair number of them.

The urns float just above the old boxwood flanking the front walk. I like the look. The boxes are planted with nicotiana mutabilis, nicotiana alata lime and petunias. No fancy plants – just a fair number of them.

Those urns and boxes read just fine, even from across the street.

Those urns and boxes read just fine, even from across the street.

Every day, I come out this front door with Howard. He is not able any more to navigate the stairs to the basement. So I put him on the front porch, drive the car around to the front, and pick him up. It takes him a while to get to the curb. I don’t mind this. I have the Wilson Foundry and Machine Company urns to look at. The landscape here has a history. It has evolved significantly over the past 88 years, and these pots are part of that.

Every day, I come out this front door with Howard. He is not able any more to navigate the stairs to the basement. So I put him on the front porch, drive the car around to the front, and pick him up. It takes him a while to get to the curb. I don’t mind this. I have the Wilson Foundry and Machine Company urns to look at. The landscape here has a history. It has evolved significantly over the past 88 years, and these pots are part of that.